We always want our bobbins to be full, cupboards full of fabric and the sewing machine to move fabric forward stitching all the time. Well, almost always. Sometimes you want the fabric to stay put, but it keeps moving and stitching. That is frustrating enough. And then, sometimes the fabric refuses to move even when you want it to.

Both are issues you do not want – and both can be resolved if you know how to control the feed dogs.

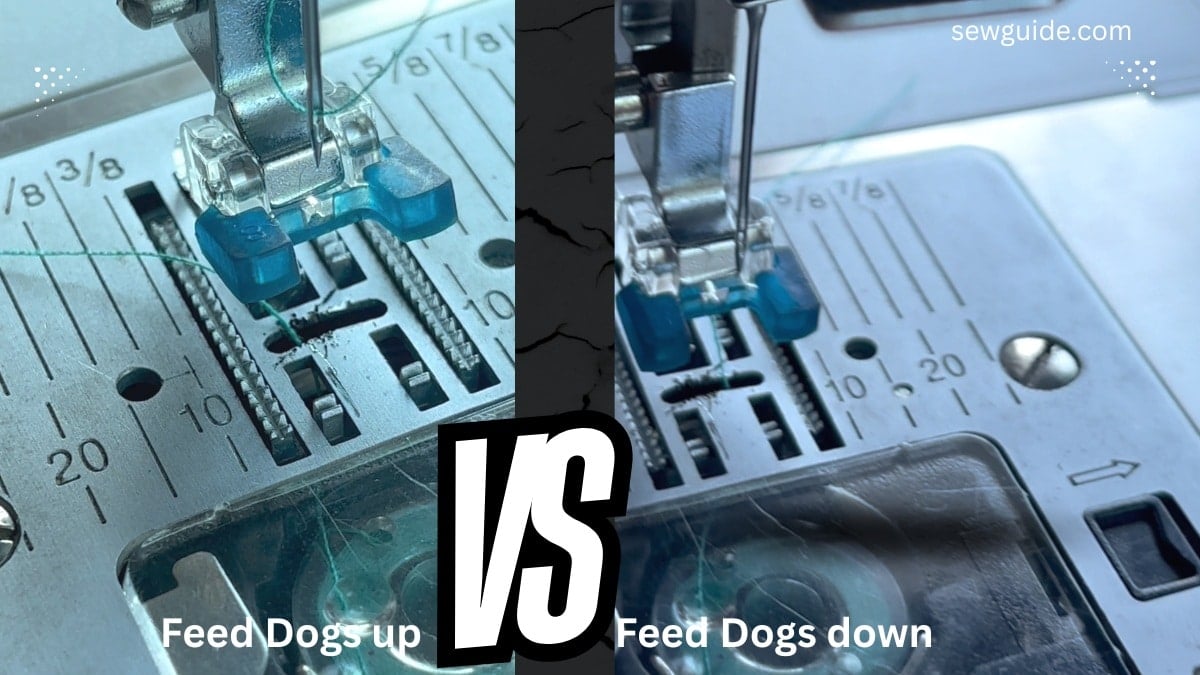

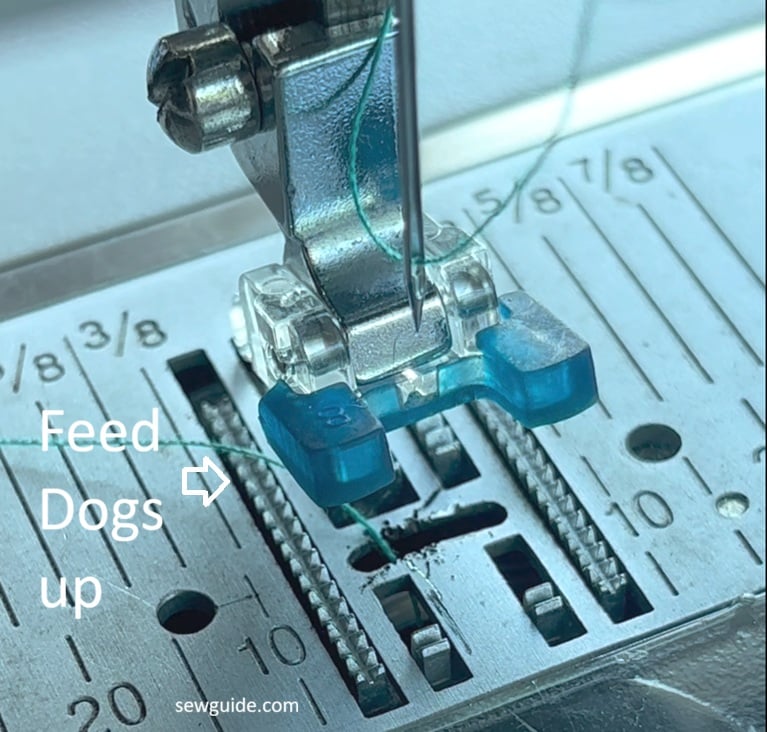

Feed Dogs are the toothed metal parts (small metal bars with teeth) under the needle plate that move the fabric forward in a sewing machine. The teeth rise up through the slots in the plate and move in a cycle—up, forward, down, and back—to grip the fabric and carry it smoothly as you sew. It determines how my fabric moves or not move when sewing. For eg in darning, I do not want the feed dogs to work. Nor do I want it to work and run away with it when I am sewing a button in place.

When I started using the button foot I hold onto to it with my dear life to make sure the needle hit the holes and the machine wouldn’t continue stitching forward, moving the needle and then breaking all my buttons. It didn’t work. But then I learned that there are ways to control the feed dogs. And the rest is history.

You cannot diminish the importance of the feed dog in your sewing life. It is the life force behind your sewing machine. If the feed dogs do not carry the fabric smoothly, it will sew in the same place. It is like walking a lot and not reaching anywhere. As if you have adjusted the stitch length to be zero and forgot about it.

There are three operations possible with it – go forward, stand still or go lower, and go back wards. Not all sewing machines do all these functions the same way.

In normal sewing Going forward is the basic operation, of course with the feed dogs raised up. There is not much I can do about this function of the feed dogs usually . I just let it operate at its own pace for all sewing.

The above won’t work. The buttons I sew like this all broke. The feed dogs started to advance fabric and the needle hit the button sideways – it was either the needle or the buttons. I thank the Sewing Gods that it was not the needle; I can handle plastic pieces but not sharp needle bits flying all around.

It started to work when I stopped the feed from moving the fabric as it stitched the button in place. The same principle works in darning and free motion embroidery. You need total control of the movement of your fabric.

disabling the feed dogs from moving forward

This is different for different machines.

In my Singer sewing machine there is a lever at the back of the machine with the feed dogs clearly marked to tell me which will raise the dogs and which will lower.

Most sewing machines have a feed dog control lever or switch located on the back or side of the machine, usually near the base. The lever is often marked with symbols that show whether the feed dogs are raised or lowered.

If you cannot locate the feed dog lever on your machine, check your sewing machine manual. Most manuals include a labeled diagram that clearly shows where the feed dog control is placed. The location and operation of the feed dog control vary by brand and machine type

Here is a video of me locating the feed dog switch on my Singer sewing machine:

Remember to switch off afterwards, other wise the fabric will not feed for sewing.

How to raise the feed dogs back

To raise the feed dogs, move the same lever or switch back to the raised position. In some machines, you may need to slowly turn the hand wheel toward you once or twice to allow the feed dogs to come back up fully.

Using the feed dog cover

My Janome sewing machine includes a small feed dog cover, which is used to stop the feed dogs from moving the fabric.

It fixes itself into small slots in the needle plate and prevents the feed dog from interfering with the movement of the fabric. This plate is placed over the feed dogs and it stops them from gripping and moving the fabric. It is commonly used for free-motion quilting, darning, embroidery, or sewing on buttons. You can also call it the darning cover plate.

In my industrial machine there is a screw which can stop the feed. I absolutely am terrified of messing up the ’till-now’ smooth operations of this machine – so I haven’t touched it.

What to do when fabric refuses to move forward

This is utterly frustrating. I will first check if I have accidentally lowered the feed dogs as described earlier and forgot to change it back to regular stitching and a raised feed dog.

Then I will check if the stitch length is accidentally reduced to zero. This can prevent the feed dog moving completely and stitch in one place.

If this is ruled out then my guess will be that it has something stuck inside preventing the teeth from moving forward. If some lint is stuck in it and it refuse to go forward – then I will do the weekly brushing to remove the dirt from underneath the needleplate and it will go back to going forwards, at its own pace.

Sewing very thick fabrics and also too many layers of fabrics also can prevent the fabric from moving forward. A walking foot can be useful when sewing multiple thick layers – it will help the feed dogs carry the fabric layers efficiently. Feed dogs move the fabric from below, while a walking foot helps move the fabric from above, so both layers travel together evenly through the sewing machine. No more shifting, stretching, or uneven feeding.

Related post: Sewing Machine stitching issues and solutions