For a big brand or a manufacturer, sewing does not happen the same way as it does it in your home. There is a system to it, there is a process. I was curious about it and here is what I learnt : as simple as it gets.

Starts with AN IDEA

Everything starts as an idea and this is conveyed to the designer as a brief. A brief is the instruction a fashion designer gets to start a collection – it can elaborate on the why, what and when of the garment. This will be based on a lot of research and trend forecast that the top echelons of the company does.

A range plan will be made to decide the number of silhouettes to be included and number of designs per silhouette.

DEVELOPING THE CONCEPT

This involves all aspects of the clothing including the material to be used, the way it will be constructed, what is the final silhouette, finishes and embellishments on it. You can decide on a theme, make a mood board for it and further develop the idea.

Each garment will be assigned a style number. This unique ID identifies that particular garment at any point of the fashion designing and manufacturing process.

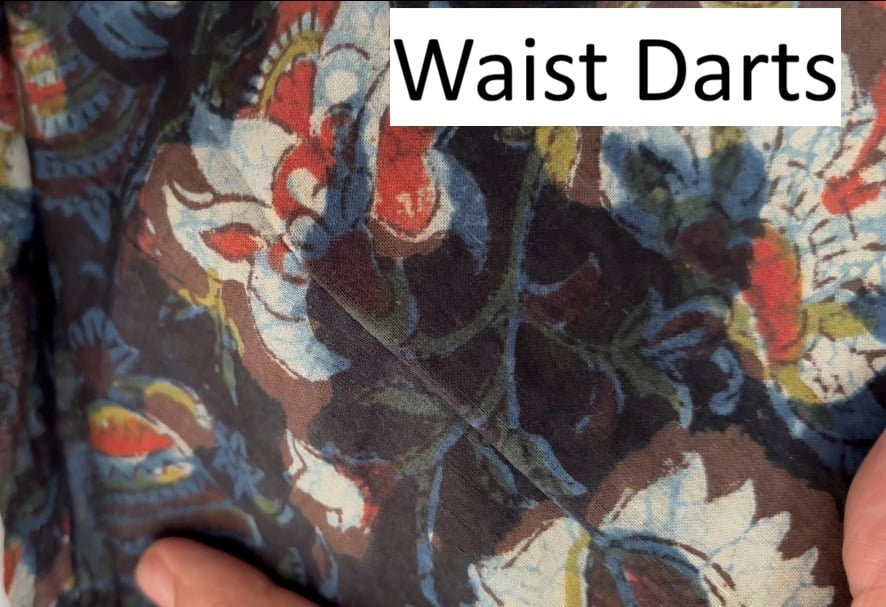

Choose fabrics and textures

Poor fabric quality can break a clothing design so this step is very important – for this the designer should have thorough knowledge of different qualities of fabrics. A balance of durability and aesthetics is essential.

Depending on the fabric used, some issues may crop up – for eg, if you are using a fragile fabric you may need to reduce unnecessary seams or forego certain embellishments.

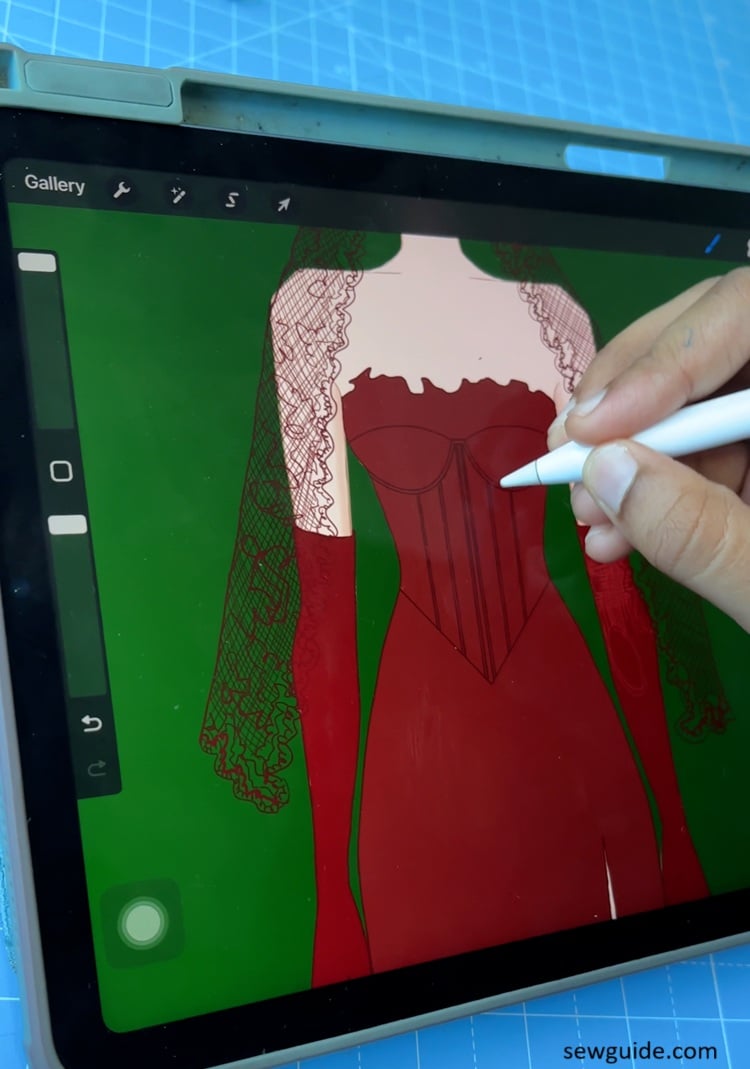

Sketching the idea (STYLIZED Fashion illustration )

Watch this video of a sketch turning into a garment:

The illustration gives a clear picture of the final garment as it would be after everything is said and done. A stylized illustration is not just a pretty drawing – It is a bit more complicated than just drawing a picture of an outfit. It can be done on paper or on digital platforms such as Adobe Illustrator, Photoshop, or specialized fashion design softwares like Procreate.

A fashion designer uses the illustration of the garment to communicate every aspect of their design to others. Your drawing should convey the idea that was given to you by way of the brief including the silhouette, fabric texture, volume, proportion, construction, fit, etc). There are many different types of illustrations you can make as you can read in this post.

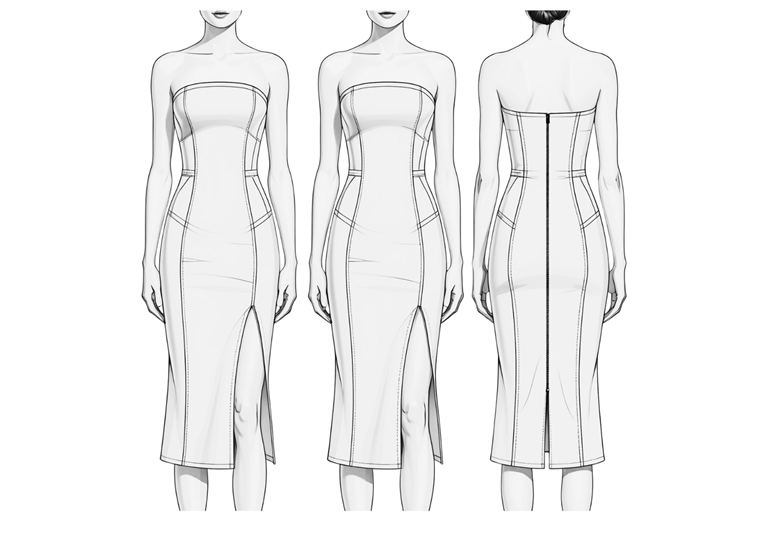

Technical drawings

At this step, you will be making clear flat technical drawings of the finalized garment. It will be simple with just outline of the clothing showing seam lines, darts, closures, stitch detailing, trims, pockets, etc accurately. There is no scope for error.

Purpose of these drawings is to communicate the design clearly to pattern makers, sample makers, and manufacturers – it will obviously look different from the stylised nature of illustrations.

A Design sheet or sketch sheet is developed that includes all the fashion sketches (both the stylised illustration as well as the flat version) of the clothing. It will also include the colorways, fabric swatches and trims meant to be used on the clothing.

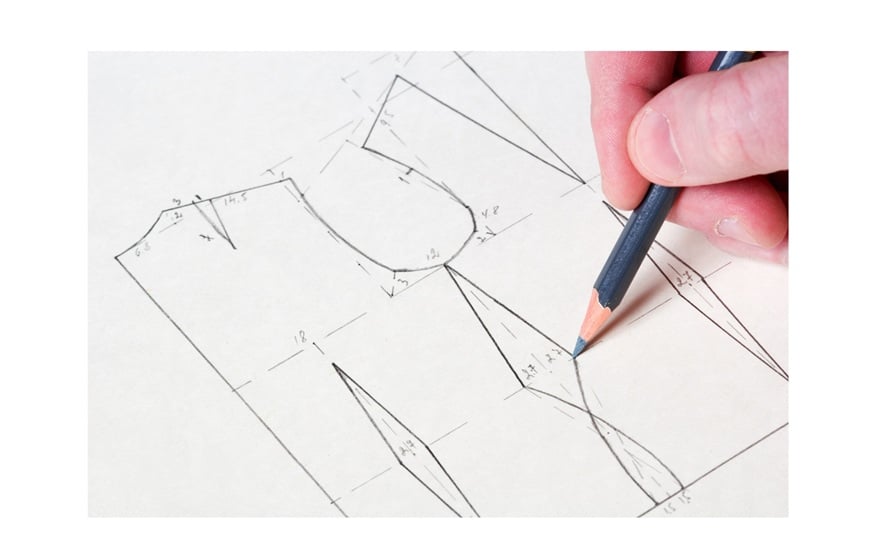

PATTERN making

A sloper is the basic foundation block made with the basic body measurements. A pattern is made on the basis of the measurement taken for the sloper.

After the approval of the pattern, the patterns are made and graded for different sizes. A developed pattern is made based on the sloper, often with ease. The sewing pattern is then used repeatedly in the manufacturing process. (Grading is the process of scaling a base pattern up or down into different sizes while keeping proportions correct.)

Make a toile /PROTOTYPE

Prototype is made from the developed pattern of the actual design. In your home sewing experience, you may make one toile at the maximum, and that too for your most precious fabric project. But in a professional project, many prototypes are made before the final production process.

Tech pack

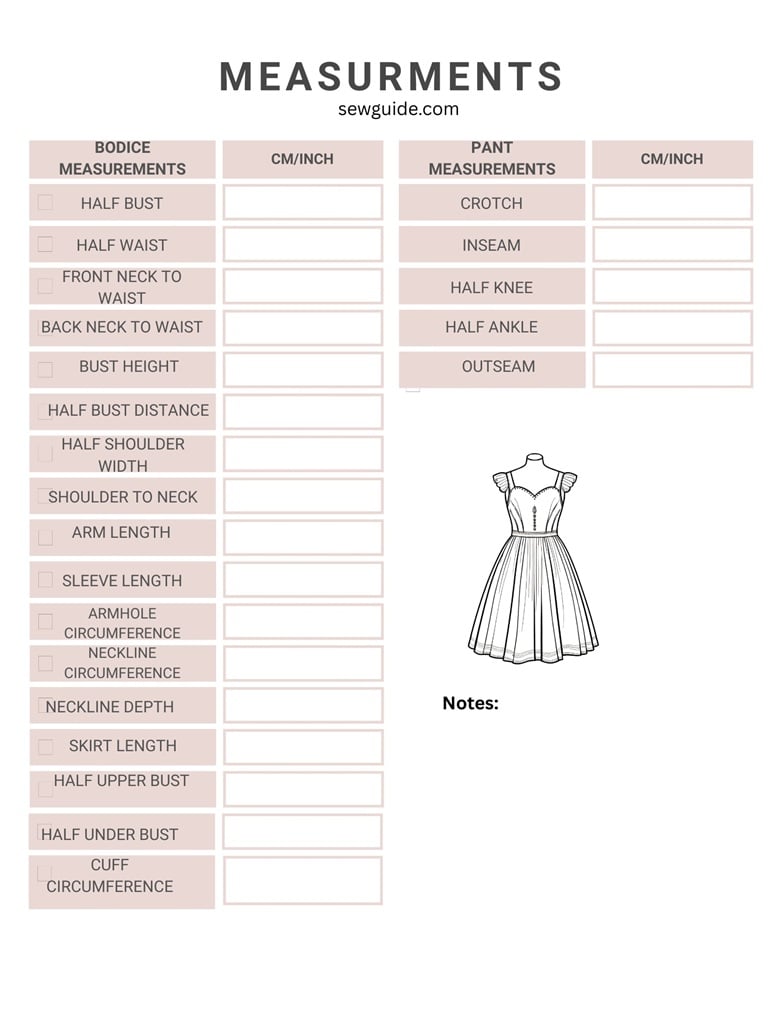

Tech pack is the full on instruction manual for production of the garment – you will be sending this to your contractor/manufacturer to sew the garment without mishaps. It describes the “how” of the production. It will have stitching diagrams, construction steps, measurement sheet etc. There will be no confusion about anything between the designer and the production team.

You can make the tech pack on whatever PLM system the brand/ company uses (Most PLM programs have standardized tech pack templates (with fields for header info, BOM, measurements, construction notes, etc.). , or specifically on adobe illustrator or indesign. Some swear by excel – you can link from the tech pack to your fashion flats, materials & colors, measurement specs, sewing process, cost etc. But there are designers who use free tech pack templates available on the internet.

Cut and stitch the final garment

Incorrect grain alignment in cutting is another deal breaker. A marker is the layout of all pattern pieces on fabric, arranged to minimize waste. This is an important step in the fashion designing process to ensure that cost is kept to a minimum.

Related posts: Definition of fashion ; Many styles in fashion